Application Overview

The spray drying granulator is suitable for preparing granules, capsules, tablet granules or coating granules of traditional Chinese patent medicines and simple preparations.

Equipment characteristics

★Multi fluid atomizer, more suitable for products with polysaccharides, strong viscosity or heat sensitivity.

★The structure of spray drying chamber, capture chamber, fluidized bed and secondary air supply system has been significantly modified, which more closely shows the characteristics of spray drying.

★Design, manufacture, and layout in accordance with GMP requirements.

★Realize continuous spray process of the extract.

★Easy and reliable operation.

★Improve spray drying efficiency.

★It is more stable than FL type fluidization, improves fluidization drying intensity, and overcomes the phenomenon of "dead bed".

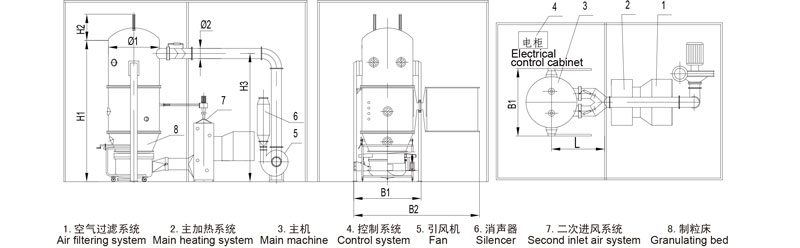

Outline Dimensional Drawing

Project specifications | 3 | 5 | 10 | 20 | 30 | 40 | 80 | 120 | 150 | ||

Volume of raw material container | L | 26 | 50 | 100 | 220 | 300 | 420 | 670 | 1000 | 1500 | |

Liquid supply volume | kg/h | 2-4 | 4-6 | 6-15 | 15-25 | 20-40 | 30-60 | 60-100 | 20-160 | 100-200 | |

Liquid specific gravity | kg/L | ≤1.3 | |||||||||

Steam | Pressure | Mpa | 0.4-0.6 | ||||||||

Consumption | Kg/h | 25 | 50 | 120 | 160 | 240 | 280 | 300 | 380 | 465 | |

Compressed air | Pressure | Mpa | 0.6 | ||||||||

Consumption | m3/min | 0.4 | 0.6 | 0.9 | 0.9 | 1.1 | 1.1 | 1.3 | 1.6 | 1.8 | |

Auxiliary blower power | Kw | 0.55 | 0.75 | 0.75 | 1.1 | 1.5 | 1.5 | 1.5 | 2.2 | 2.2 | |

Induced draft fan power | Kw | 3 | 4 | 7.5 | 11 | 18.5 | 18.5 | 22 | 30 | 37 | |

Host size | H1(mm) | 1900 | 2360 | 2680 | 3150 | 3630 | 3630 | 4120 | 5050 | 5400 | |

H2(mm) | 190 | 260 | 340 | 490 | 540 | 590 | 690 | 890 | 990 | ||

H3(mm) | 1680 | 2140 | 2460 | 2930 | 3410 | 3410 | 3900 | 4830 | 5180 | ||

?1(mm) | 400 | 550 | 700 | 1000 | 1100 | 1200 | 1400 | 1800 | 2000 | ||

?2(mm) | 150 | 180 | 180 | 250 | 280 | 280 | 315 | 355 | 355 | ||

B(mm) | 860 | 1010 | 1160 | 1460 | 1560 | 1660 | 1860 | 2260 | 2460 | ||

L(mm) | 1050 | 1050 | 1250 | 1400 | 1450 | 1500 | 1600 | 1800 | 2000 | ||

All parameters are for reference only, and our company has the right to make changes based on the material situation without prior notice.